Processing Services

At Toyo Brazing Vietnam, we perform “brazing” using mesh belt continuous furnaces and batch-type vacuum furnaces.

What is Brazing?

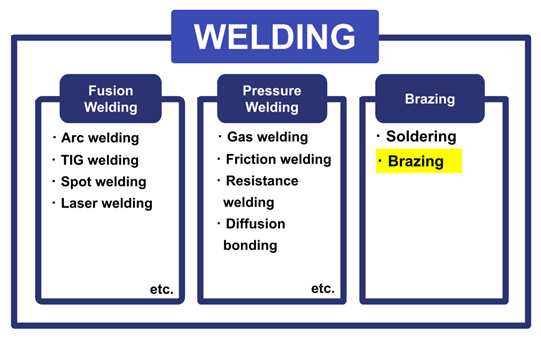

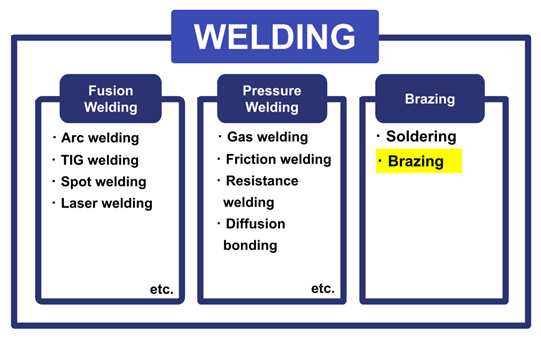

Brazing is a type of welding.

When brazing is performed using a furnace, it is referred to as “Brazing”.

▼ Brazing

1)Mesh belt brazing furnace

-

- Capable of handling small-lot production.

- Relatively low processing cost.

2)Batch-Type Vacuum Furnace

- Enables more precise temperature control.

- Allows brazing of dissimilar materials (iron + non-iron).

Example: Iron + SUS, SUS + SUS, Iron + Copper, etc.

1)

2)

Benefits of Brazing

- Enables bonding of complex shapes and simultaneous joining of multiple points.

- Suitable for joining thin-walled structures and small components.

- Ideal for mass production.

- Brazed parts offer high airtightness, suitable for hydraulic and high-pressure gas components.

- Brazed joints provide strength and toughness equal to or greater than the base material.

- Consistent furnace temperature ensures high product quality with minimal variation.

- Processed in an oxygen-free or vacuum atmosphere, preventing oxidation and ensuring clean joints.

→ No need for post-treatment (e.g., pickling, barrel polishing), enabling direct surface finishing.

Our Heat Treatment Services

▼ Annealing

1)Annealing

- Softens the material to improve workability for forging, cutting, pressing, etc.

- Uniforms the internal structure and removes internal stress.

→ Prevents cracking and warping.

→ Enhances durability, safety, and overall product quality.

2)Magnetic Annealing

- Demagnetization improves functionality in electronic component applications.

- Also provides the same benefits as standard annealing.

▼ Solution Treatment

- Suppresses chromium precipitation and prevents sensitization.

→ Enhances corrosion resistance of stainless steel.

→ Improves strength.

- Eliminates internal stress.

- Improves the internal structure and helps maintain long-term physical properties.

If you have any questions about brazing, annealing, or solution treatment, feel free to

contact Toyo Brazing Vietnam.